Kangtao

Widely used in roofing sheet, window-shades, car ceiling, the shell of the car, air conditioner.outer shell of water machine, steel structure etc

SNI, CE, ISO9001

Matt, Orange, Film, FVDF HDP, SMP PE, PU

600-1250mm

0.12-1.2mm

Pre-painted Galvanized Steel Coil/ PPGI Steel Coil

ASTM, JIS, GB, EN

Hot Rolled Cold Rolled

SGCC, DX51D, DX52D, DX53D,

Z41-Z60

| Availability: | |

|---|---|

| Quantity: | |

| Product Name | Pre-painted Galvanized Steel Coil/ PPGI Steel Coil |

| Materials | SGCC, DX51D, DX52D, DX53D, |

| Technique | Cold rolled, Hot rolled |

| Surface Treatment | Matt, Orange, Film, FVDF HDP, SMP PE, PU |

| Standard | ASTM, JIS, GB, EN |

| Certificate | SNI, CE, ISO9001 |

| Payment Terms | TT, 30% TT and balance LC |

| Application | Widely used in roofing sheet, window-shades, car ceiling, the shell of the car, air conditioner.outer shell of water machine, steel structure etc |

| Width | 600-1250mm |

| Thickness | 0.12-1.2mm |

| Tolerance | ±1 |

| Package | Standard sea-package |

Product Introduction:

Analysis of products

Common Color:

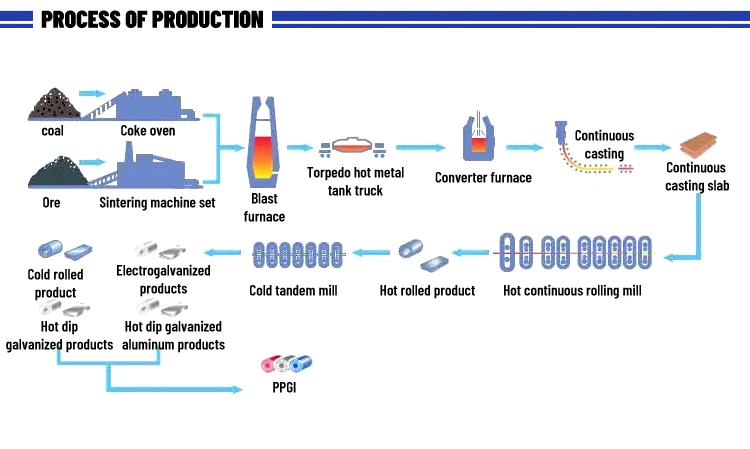

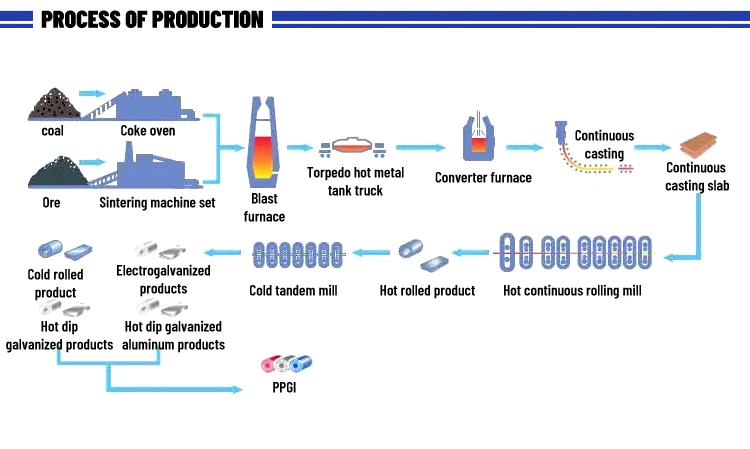

Production Line:

Measurement and inspection:

Packing and Delivery:

The packaging and transportation process of steel coils mainly includes the following links:First, the packaging process is selected according to the type of steel coil and the transportation distance. Simple packaging is suitable for short distance transportation, only 1 to 3 steel strips are bound in the outer circle; Fine packaging needs to use anti-rust paper, plastic film, internal and external Angle protection, protection plate and other materials to wrap the steel coil, and through circumferential and radial bundling reinforcement (such as 6 steel strips for large coils, 4 for small coils). During the packaging process, it is also necessary to paste rain proof labels, and set a protective layer on the end face to reduce mechanical damage. In transportation, light packaging and water transport are usually used for short distances, while waterproof and moisture-proof measures are required for long distances or high value-added products, such as the use of framed steel containers or galvanized iron sheets. In railway transportation, special containers can reduce the amount of reinforcement materials and improve the loading efficiency; Road transportation needs to be fixed by steel wire rope or rubber pad to avoid rolling risk.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

| Product Name | Pre-painted Galvanized Steel Coil/ PPGI Steel Coil |

| Materials | SGCC, DX51D, DX52D, DX53D, |

| Technique | Cold rolled, Hot rolled |

| Surface Treatment | Matt, Orange, Film, FVDF HDP, SMP PE, PU |

| Standard | ASTM, JIS, GB, EN |

| Certificate | SNI, CE, ISO9001 |

| Payment Terms | TT, 30% TT and balance LC |

| Application | Widely used in roofing sheet, window-shades, car ceiling, the shell of the car, air conditioner.outer shell of water machine, steel structure etc |

| Width | 600-1250mm |

| Thickness | 0.12-1.2mm |

| Tolerance | ±1 |

| Package | Standard sea-package |

Product Introduction:

Analysis of products

Common Color:

Production Line:

Measurement and inspection:

Packing and Delivery:

The packaging and transportation process of steel coils mainly includes the following links:First, the packaging process is selected according to the type of steel coil and the transportation distance. Simple packaging is suitable for short distance transportation, only 1 to 3 steel strips are bound in the outer circle; Fine packaging needs to use anti-rust paper, plastic film, internal and external Angle protection, protection plate and other materials to wrap the steel coil, and through circumferential and radial bundling reinforcement (such as 6 steel strips for large coils, 4 for small coils). During the packaging process, it is also necessary to paste rain proof labels, and set a protective layer on the end face to reduce mechanical damage. In transportation, light packaging and water transport are usually used for short distances, while waterproof and moisture-proof measures are required for long distances or high value-added products, such as the use of framed steel containers or galvanized iron sheets. In railway transportation, special containers can reduce the amount of reinforcement materials and improve the loading efficiency; Road transportation needs to be fixed by steel wire rope or rubber pad to avoid rolling risk.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.