Kangtao

Decoration Kitchen etc.

ISO9001

Grade 200, Grade 300, Grade 400

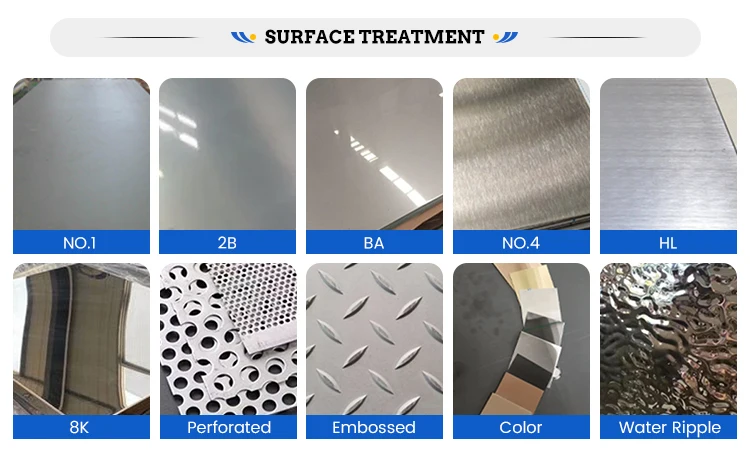

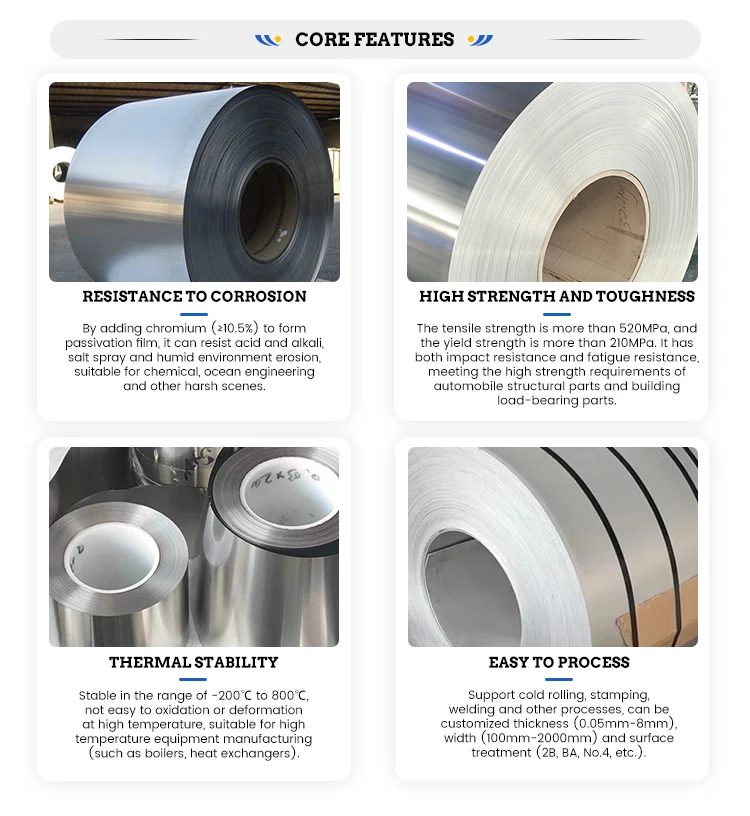

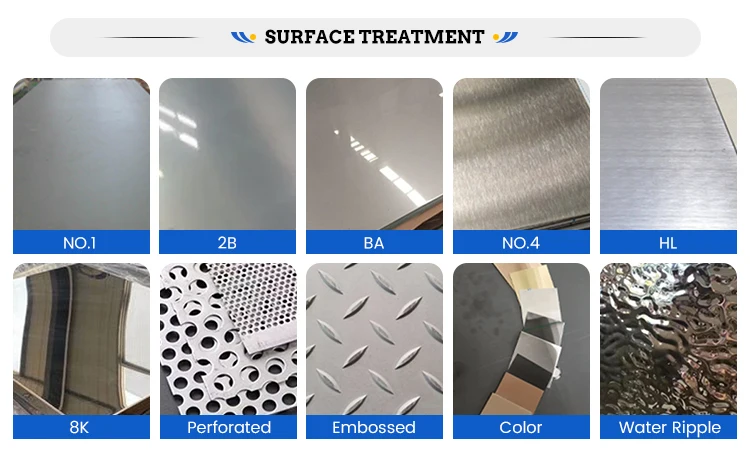

2D 2B BA 8K NO.1 NO.4 HL EMBOSSED

customized

customized

stainless steel coil

ASTM, JIS, GB, EN

Cold Rolled

304/201/202/430/410/630/316/316L/304

Steel Coil

customized

| Availability: | |

|---|---|

| Quantity: | |

| Product Name | Stainless Steel Coil |

| Length | As required |

| Width | 3mm-2000mm or as required |

| Thickness | 0.1mm-3mm or as required |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN,etc |

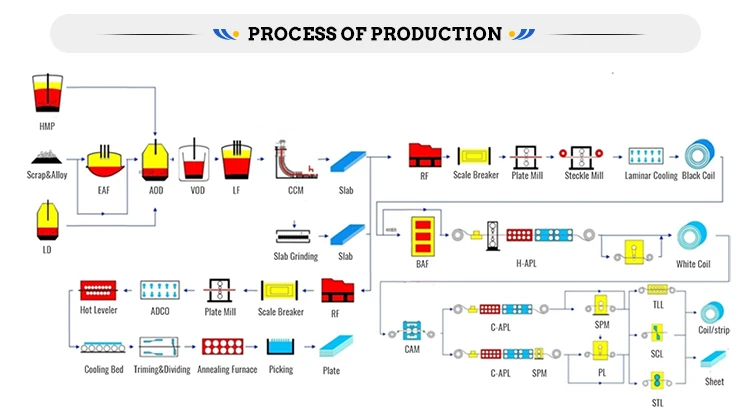

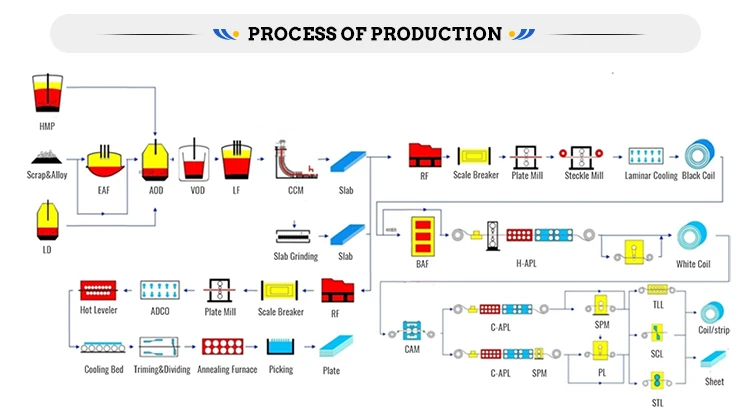

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness Tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L |

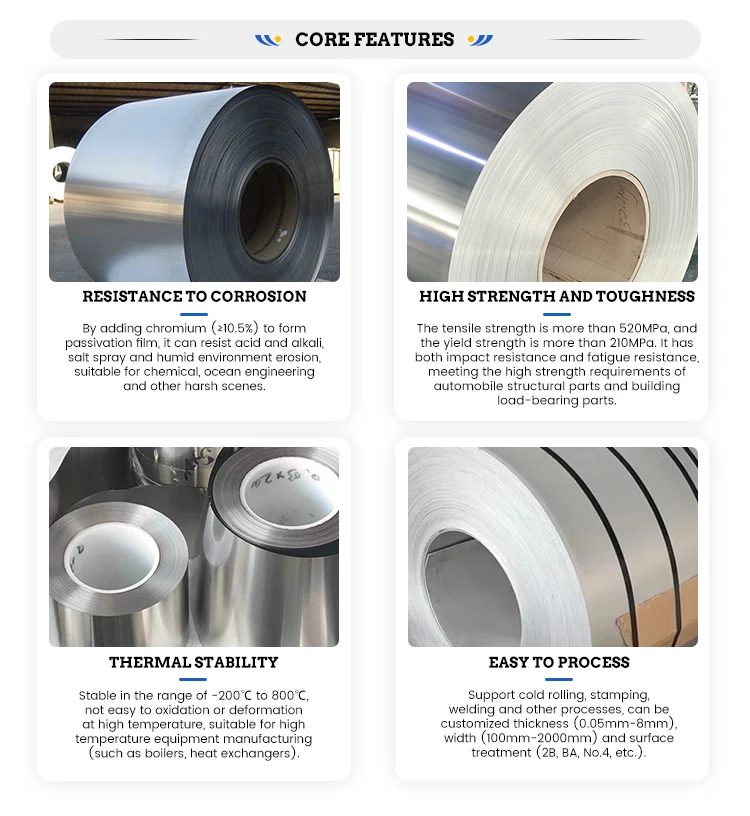

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components. It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 5 tons |

| Shipment Time | Within 15-20 workdays after receiving deposit or L/C |

| Export Packing | Waterproof paper, and steel strip packed. Standard Export Seaworthy Package. Suit for all kinds of transport,or as required |

| Capacity | 100,000 tons/year |

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

| Product Name | Stainless Steel Coil |

| Length | As required |

| Width | 3mm-2000mm or as required |

| Thickness | 0.1mm-3mm or as required |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN,etc |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness Tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components. It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 5 tons |

| Shipment Time | Within 15-20 workdays after receiving deposit or L/C |

| Export Packing | Waterproof paper, and steel strip packed. Standard Export Seaworthy Package. Suit for all kinds of transport,or as required |

| Capacity | 100,000 tons/year |

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.