Kangtao

| Availability: | |

|---|---|

| Quantity: | |

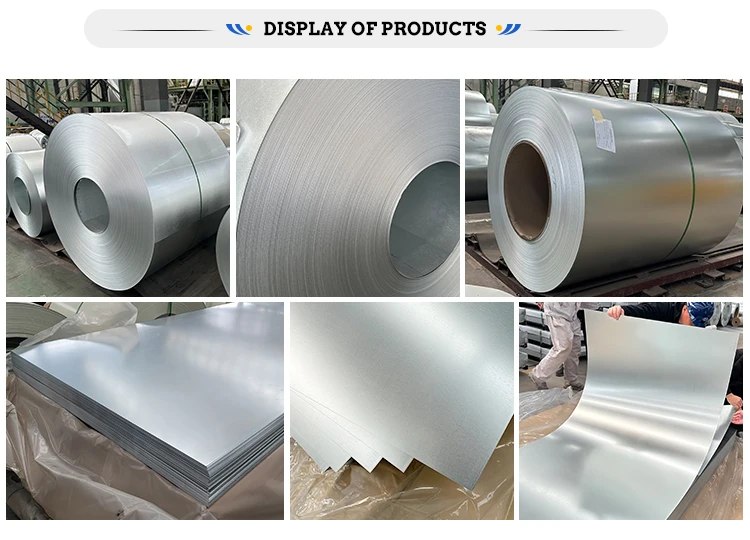

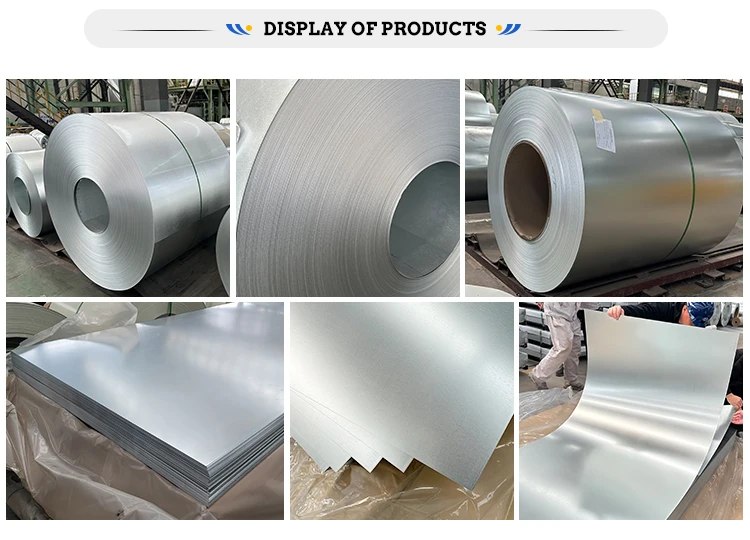

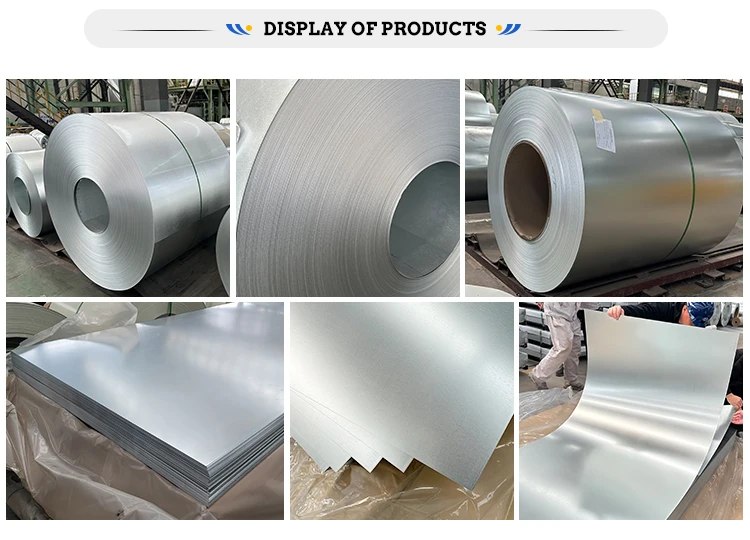

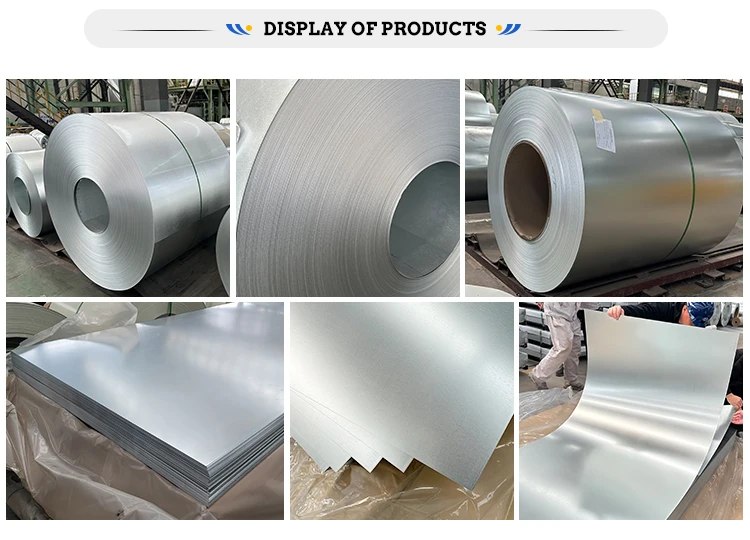

| Product Name | No/Zero Spangle Galvanized Steel Coil |

| Steel Grade | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement |

| Type | Coil/Sheet/Plate/Strip |

| Thickness | 0.12-6.00mm, or customer's requirement |

| Width | 600mm-1500mm, according to customer's requirement |

| Type of Coating | Hot Dipped Galvanized Steel(HDGI) |

| Zinc Coating | 30-275g/m2 |

| Surface Treatment | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

| Spangle | Zero spangle, spangle-free(FS) |

| ID | 508mm/610mm |

| Coil Weight | 3-20 metric ton per coil |

| Package | Water proof paper is inner packing, galvanized steel or coated steel sheet is outer packing , side guard plate, then wrapped by seven steel belt or according to customer's requirement |

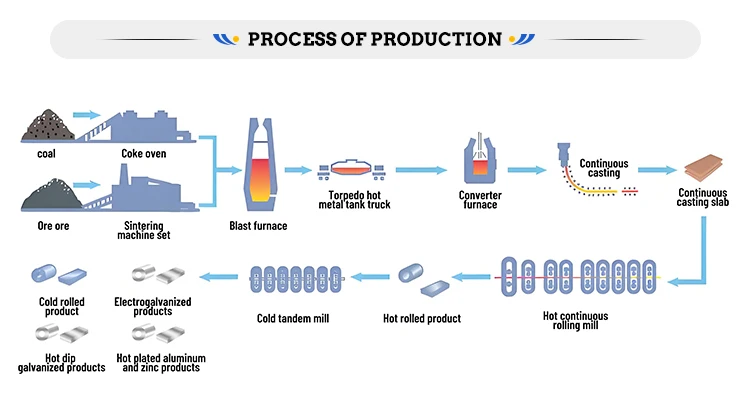

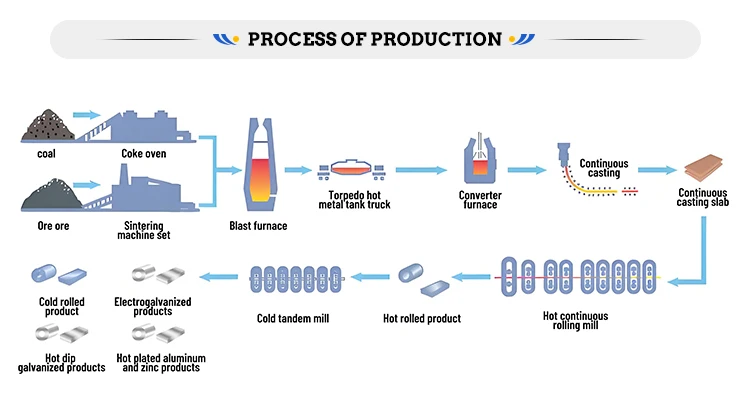

| Production Stage | Technical Highlights |

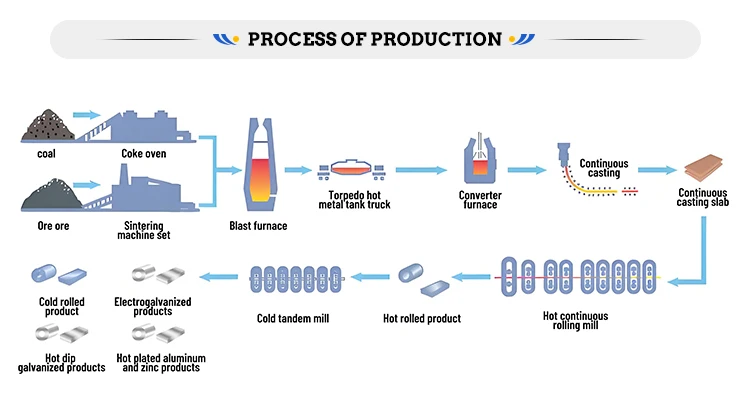

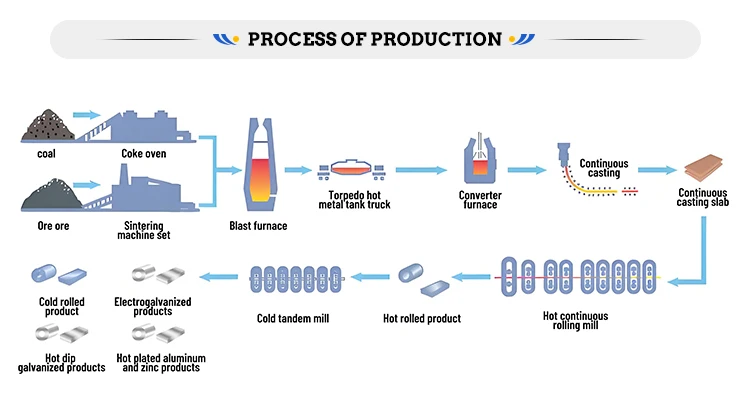

| Raw Material Refining | Utilization of ultra-low carbon steel (C≤0.02%) smelting to ensure substrate ductility and weldability . |

| Galvanizing Process | Air knife precision control of zinc coating thickness (dual-side adjustable range: 60-275g/m²), with zinc purity ≥99.995% . |

| Surface Treatment | Optional chromate passivation or eco-friendly chromium-free passivation, compliant with RoHS directives . |

| Intelligent Slitting | Laser width measurement system achieves ±0.5mm cutting accuracy; coil weight tolerance ≤1% . |

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

| Product Name | No/Zero Spangle Galvanized Steel Coil |

| Steel Grade | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement |

| Type | Coil/Sheet/Plate/Strip |

| Thickness | 0.12-6.00mm, or customer's requirement |

| Width | 600mm-1500mm, according to customer's requirement |

| Type of Coating | Hot Dipped Galvanized Steel(HDGI) |

| Zinc Coating | 30-275g/m2 |

| Surface Treatment | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

| Spangle | Zero spangle, spangle-free(FS) |

| ID | 508mm/610mm |

| Coil Weight | 3-20 metric ton per coil |

| Package | Water proof paper is inner packing, galvanized steel or coated steel sheet is outer packing , side guard plate, then wrapped by seven steel belt or according to customer's requirement |

| Production Stage | Technical Highlights |

| Raw Material Refining | Utilization of ultra-low carbon steel (C≤0.02%) smelting to ensure substrate ductility and weldability . |

| Galvanizing Process | Air knife precision control of zinc coating thickness (dual-side adjustable range: 60-275g/m²), with zinc purity ≥99.995% . |

| Surface Treatment | Optional chromate passivation or eco-friendly chromium-free passivation, compliant with RoHS directives . |

| Intelligent Slitting | Laser width measurement system achieves ±0.5mm cutting accuracy; coil weight tolerance ≤1% . |

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

| Production Stage | Technical Highlights |

| Raw Material Refining | Utilization of ultra-low carbon steel (C≤0.02%) smelting to ensure substrate ductility and weldability . |

| Galvanizing Process | Air knife precision control of zinc coating thickness (dual-side adjustable range: 60-275g/m²), with zinc purity ≥99.995% . |

| Surface Treatment | Optional chromate passivation or eco-friendly chromium-free passivation, compliant with RoHS directives . |

| Intelligent Slitting | Laser width measurement system achieves ±0.5mm cutting accuracy; coil weight tolerance ≤1% . |

| Production Stage | Technical Highlights |

| Raw Material Refining | Utilization of ultra-low carbon steel (C≤0.02%) smelting to ensure substrate ductility and weldability . |

| Galvanizing Process | Air knife precision control of zinc coating thickness (dual-side adjustable range: 60-275g/m²), with zinc purity ≥99.995% . |

| Surface Treatment | Optional chromate passivation or eco-friendly chromium-free passivation, compliant with RoHS directives . |

| Intelligent Slitting | Laser width measurement system achieves ±0.5mm cutting accuracy; coil weight tolerance ≤1% . |