Kangtao

500-1500mm

0.8-2.5mm

Cold Rolled Steel Coil

SPCC, DC01,DC02, DC03, DC04, ST12

As request

| Availability: | |

|---|---|

| Quantity: | |

| Product Name | Cold Rolled Steel Coil |

| Material | SPCC, DC01,DC02, DC03, DC04, ST12 |

| Thickness | 0.8-2.5mm |

| Width | 500-1500mm |

| Length | As request |

| Oiled or Non-oiled | Slightly Oiled |

| Coil Weight | 3-8 Tons |

| Hardness | Mid hard/Full hard |

| Coil ID | 508/610mm |

| Delivery Time | 10-25 days |

| MOQ | 25 Tons |

| Payment Term | 30%T/T Advance + 70% Balance |

| Package | Standard Sea Worthy Package |

| Industry | Typical Uses | Recommended brand number |

| Automobile manufacturing | Body panels, doors, hood (high deep impact performance) | DC05/DC06 (European standard), SPCE (Japanese standard) |

| Home appliance industry | Refrigerator shell, washing machine inner tube, air conditioning panel (high surface finish) | ST12 (German standard), SPCC (American Standard) |

| Construction project | Light steel keel, curtain wall supporting structure, roof plate (high strength weather resistance) | Q345B (GB), CR4 (British standard) |

| Manufacturing of machinery | Precision instrument support, machine tool housing, conveyor belt roller (high dimensional stability) | Q235A (National standard), ASTM A366 (American Standard) |

| The Packaging industry | Metal tank, bottle cap (ultra-thin specification processing) | DC01 (European standard), SPCC-1B (rolled hard coil) |

| Electronic device manufacturing | Circuit board substrate, electronic component housing, shielding materials (high conductivity and corrosion resistance) | C1020 (Japanese standard), H08A (Chinese standard) |

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

| Product Name | Cold Rolled Steel Coil |

| Material | SPCC, DC01,DC02, DC03, DC04, ST12 |

| Thickness | 0.8-2.5mm |

| Width | 500-1500mm |

| Length | As request |

| Oiled or Non-oiled | Slightly Oiled |

| Coil Weight | 3-8 Tons |

| Hardness | Mid hard/Full hard |

| Coil ID | 508/610mm |

| Delivery Time | 10-25 days |

| MOQ | 25 Tons |

| Payment Term | 30%T/T Advance + 70% Balance |

| Package | Standard Sea Worthy Package |

| Industry | Typical Uses | Recommended brand number |

| Automobile manufacturing | Body panels, doors, hood (high deep impact performance) | DC05/DC06 (European standard), SPCE (Japanese standard) |

| Home appliance industry | Refrigerator shell, washing machine inner tube, air conditioning panel (high surface finish) | ST12 (German standard), SPCC (American Standard) |

| Construction project | Light steel keel, curtain wall supporting structure, roof plate (high strength weather resistance) | Q345B (GB), CR4 (British standard) |

| Manufacturing of machinery | Precision instrument support, machine tool housing, conveyor belt roller (high dimensional stability) | Q235A (National standard), ASTM A366 (American Standard) |

| The Packaging industry | Metal tank, bottle cap (ultra-thin specification processing) | DC01 (European standard), SPCC-1B (rolled hard coil) |

| Electronic device manufacturing | Circuit board substrate, electronic component housing, shielding materials (high conductivity and corrosion resistance) | C1020 (Japanese standard), H08A (Chinese standard) |

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

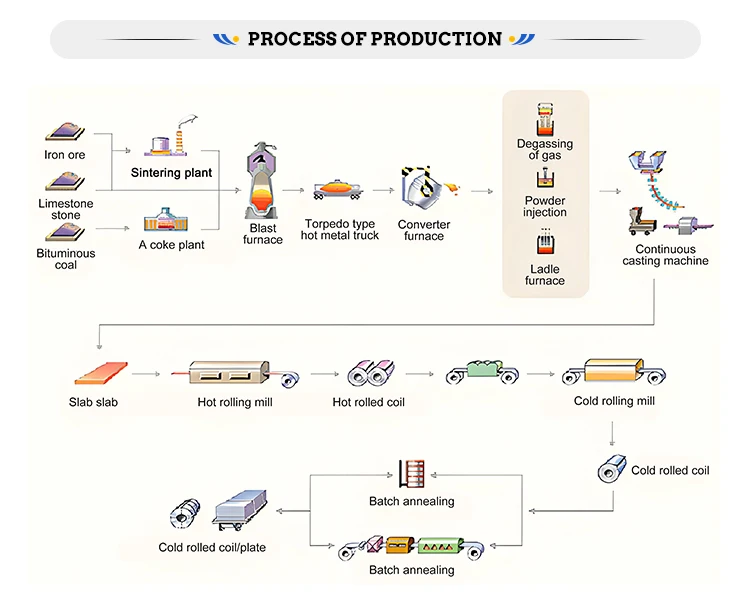

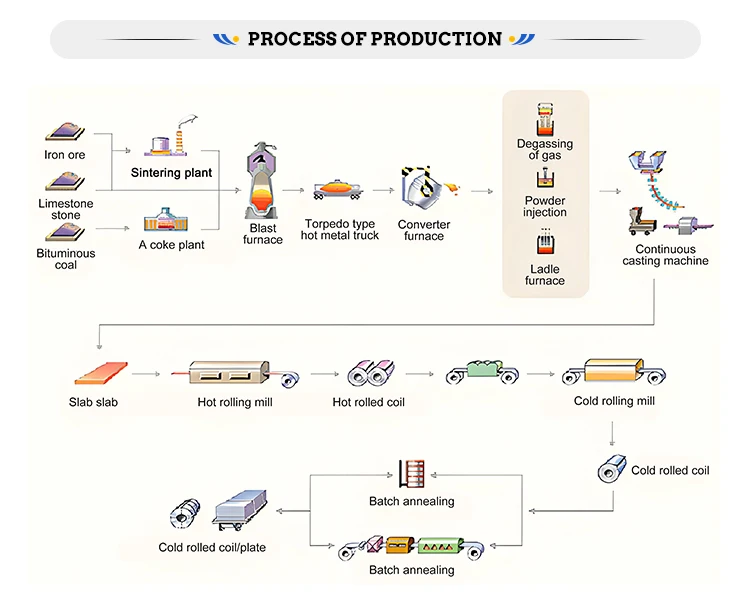

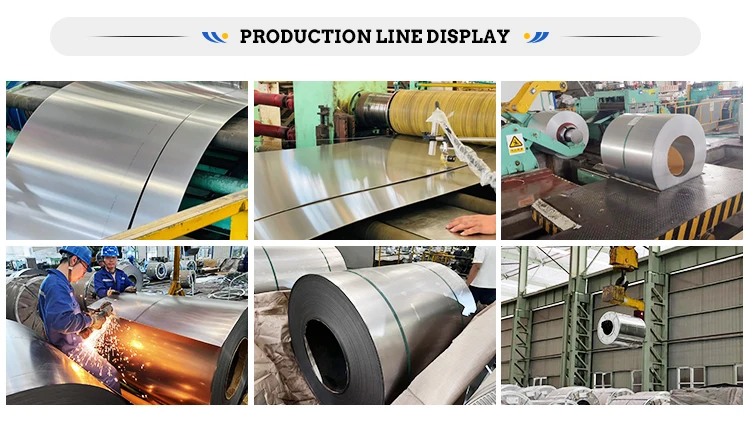

The whole process production process

The whole process production process The whole process production process

The whole process production process

| Industry | Typical Uses | Recommended brand number |

| Automobile manufacturing | Body panels, doors, hood (high deep impact performance) | DC05/DC06 (European standard), SPCE (Japanese standard) |

| Home appliance industry | Refrigerator shell, washing machine inner tube, air conditioning panel (high surface finish) | ST12 (German standard), SPCC (American Standard) |

| Construction project | Light steel keel, curtain wall supporting structure, roof plate (high strength weather resistance) | Q345B (GB), CR4 (British standard) |

| Manufacturing of machinery | Precision instrument support, machine tool housing, conveyor belt roller (high dimensional stability) | Q235A (National standard), ASTM A366 (American Standard) |

| The Packaging industry | Metal tank, bottle cap (ultra-thin specification processing) | DC01 (European standard), SPCC-1B (rolled hard coil) |

| Electronic device manufacturing | Circuit board substrate, electronic component housing, shielding materials (high conductivity and corrosion resistance) | C1020 (Japanese standard), H08A (Chinese standard) |

| Industry | Typical Uses | Recommended brand number |

| Automobile manufacturing | Body panels, doors, hood (high deep impact performance) | DC05/DC06 (European standard), SPCE (Japanese standard) |

| Home appliance industry | Refrigerator shell, washing machine inner tube, air conditioning panel (high surface finish) | ST12 (German standard), SPCC (American Standard) |

| Construction project | Light steel keel, curtain wall supporting structure, roof plate (high strength weather resistance) | Q345B (GB), CR4 (British standard) |

| Manufacturing of machinery | Precision instrument support, machine tool housing, conveyor belt roller (high dimensional stability) | Q235A (National standard), ASTM A366 (American Standard) |

| The Packaging industry | Metal tank, bottle cap (ultra-thin specification processing) | DC01 (European standard), SPCC-1B (rolled hard coil) |

| Electronic device manufacturing | Circuit board substrate, electronic component housing, shielding materials (high conductivity and corrosion resistance) | C1020 (Japanese standard), H08A (Chinese standard) |