| Product Name | Profile Steel(Angle Steel、H-Beam、I-Beam、Channel Steel、Flat Steel、Railway Steel Rail) |

| Grade | Q235 Q235B Q345 Q345B SS400 |

| Technique | Hot Rolled、Cold rolled、Galvanized |

| Length | 6-12m |

| Flange Width | 100-500mm |

| Flange Thickness | 6mm - 64mm |

| Web Width | 96mm - 1056mm |

| Web Thickness | 6mm-16mm |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Alloy Or Not | Non-Alloy |

| Invoicing | by theoretical weight |

| Delivery Time | 8-14 days |

| Shape | U-shape 、C-shape、Z-shape |

| Application | Construction structure |

| Packing | Export standard packing or according to customers’ requirement |

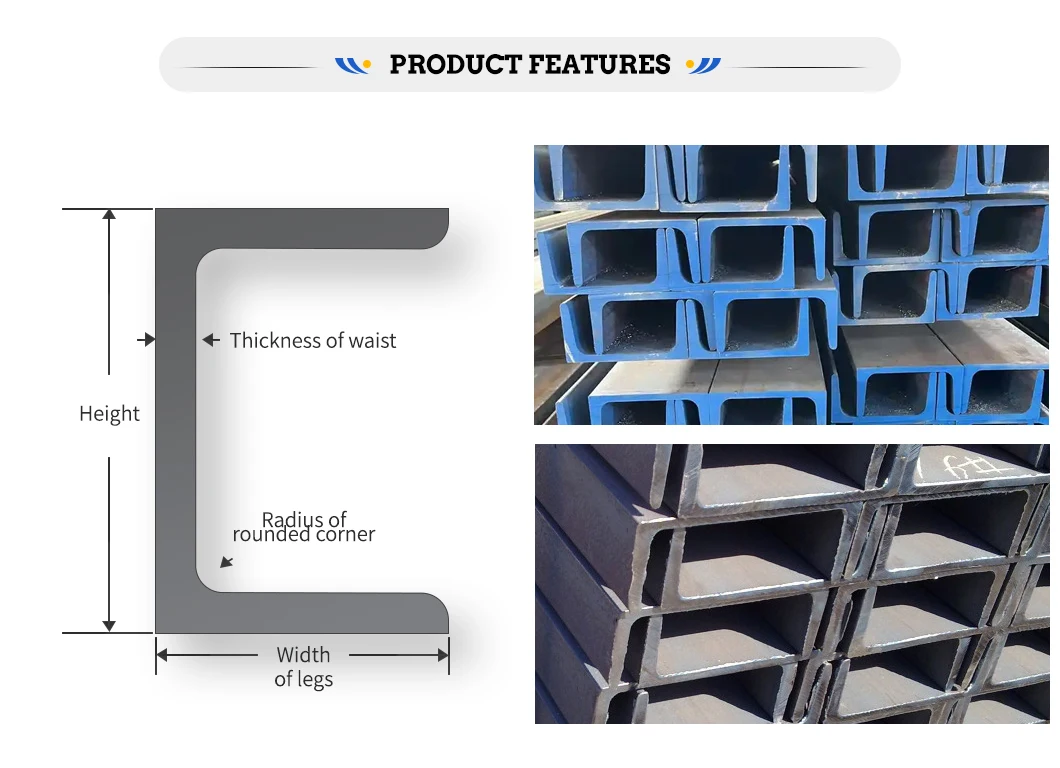

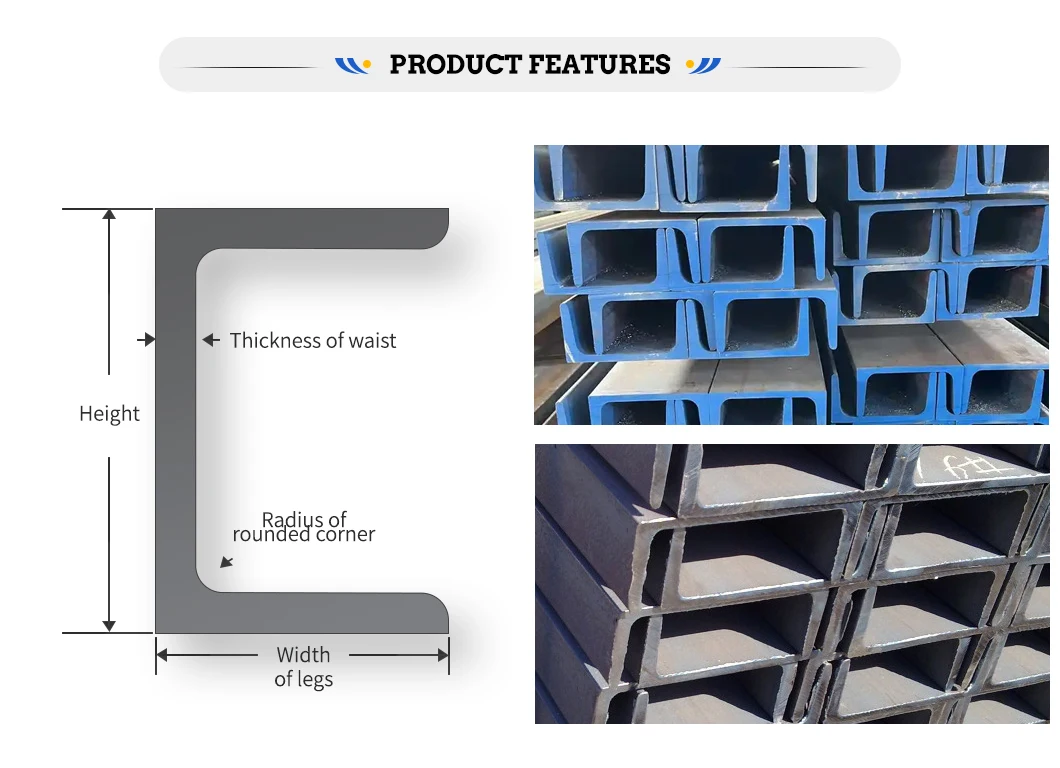

1. Shape & Structure - Resembles the letter "C"or "U" when viewed from the end. - Consists of a vertical web and two horizontal flanges(top and bottom). - Available in equal flange and unequal flange designs. 2. Material Types - Hot-rolled channel steel: Strong and durable, commonly used in construction. - Cold-formed channel steel: Lighter, used in lightweight structures. - Galvanized channel steel: Corrosion-resistant, ideal for outdoor use. 3. Standard Specifications - Standards (e.g., EN, DIN, JIS, GB, ASTM A36, A572) - Common sizes: Depth (50mm–400mm), Flange width (30mm–100mm), Thickness (3mm–20mm).

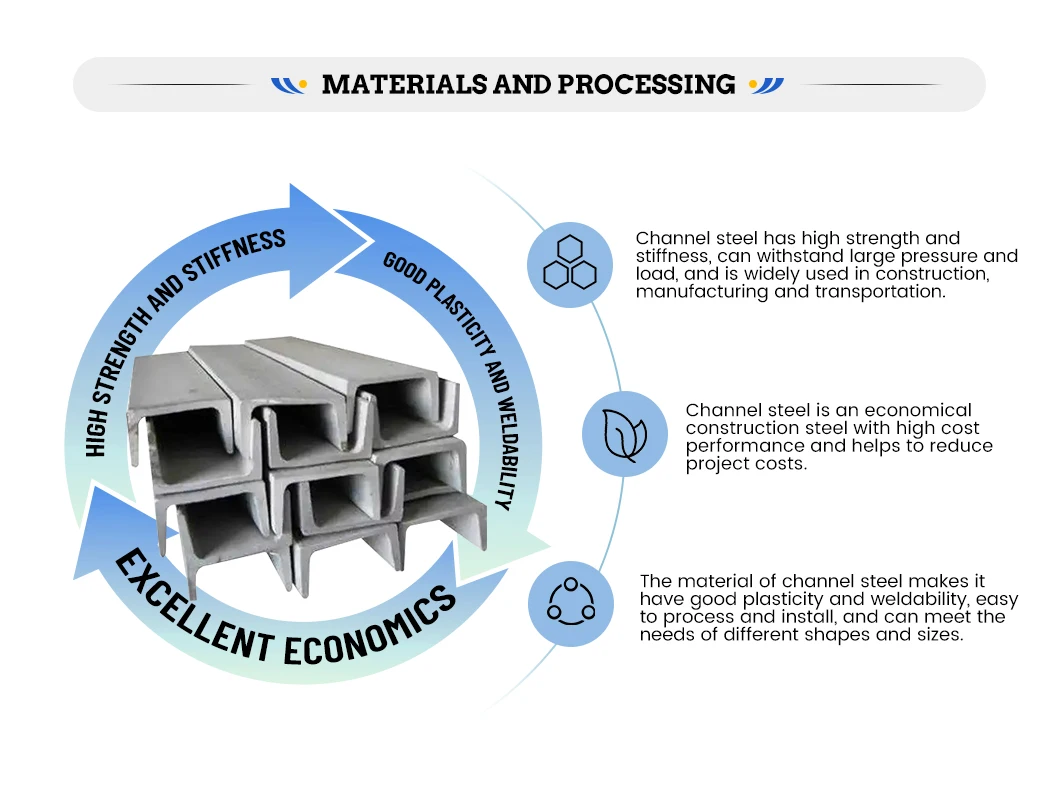

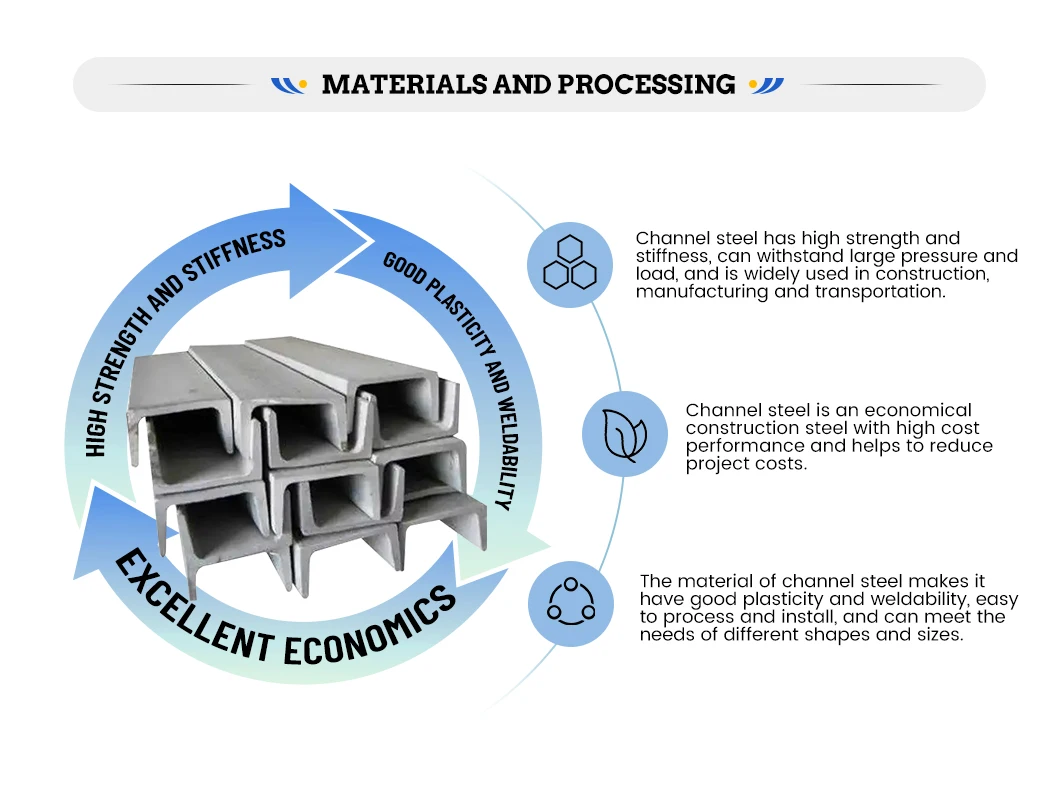

Advantages of channel steel

High strength and high load-bearing capacity: our channel steel has high tensile strength and yield strength, can with stand large load and pressure, suitable for supporting members and connectors in building structures, improve the stability of the overall structure. Good processing performance and adaptability: our channel steel is easy to cut, bend and weld, with good plasticity and weldability, can adapt to different construction needs, improve construction efficiency. High cost effectiveness and environmental protection: compared with other metal materials, channel steel has lower cost and higher cost performance, which helps to reduce project costs. In addition, channel steel is an environmentally friendly material that can be recycled, reducing the damage to the environment.

Channel steel production process

·Raw material preparation: Select billets that meet the requirements as raw materials, usually specific alloy steel, to ensure the performance of channel steel.·Heating: The billet is heated to a high temperature (e.g., above 1000 ° C) to enhance its plasticity and deformation ability.·Rolling: The billet is gradually rolled into the shape of a channel steel through the roughing and finishing processes. Rough rolling thinns the material and initially forms the groove structure, while finishing rolling further refines the groove structure.·Ultra-fast cooling: after finishing rolling, ultra-fast cooling equipment is added, and the surface temperature of the billet is quickly reduced to 500℃ ~ 800℃ by means of water spraying, so as to refine the grain structure and improve the strength and toughness.·Straightening: the cooled channel steel is sent to the straightener to straighen, remove bending and distortion, and ensure that the surface is flat. Cutting and sectioning: cut the channel steel to the required length according to customer requirements.·Surface treatment: spray painting, spraying or chemical treatment of channel steel to enhance its corrosion resistance.·Quality inspection: Check the appearance, size, physical and chemical properties of finished products to ensure compliance with standards.·Packing and warehousing: qualified channel steel for packaging, and arrange transportation and storage. The temperature, pressure and cooling parameters should be strictly controlled in the whole production process to ensure the dimensional accuracy, mechanical properties and surface quality of the channel steel.

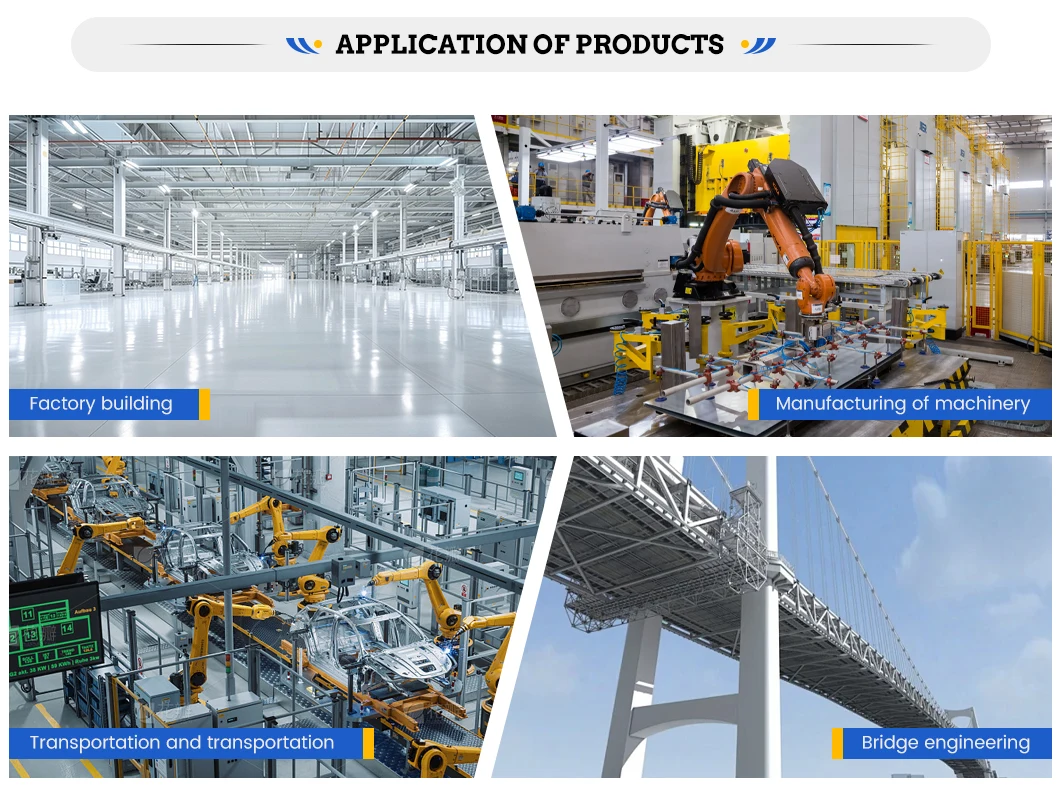

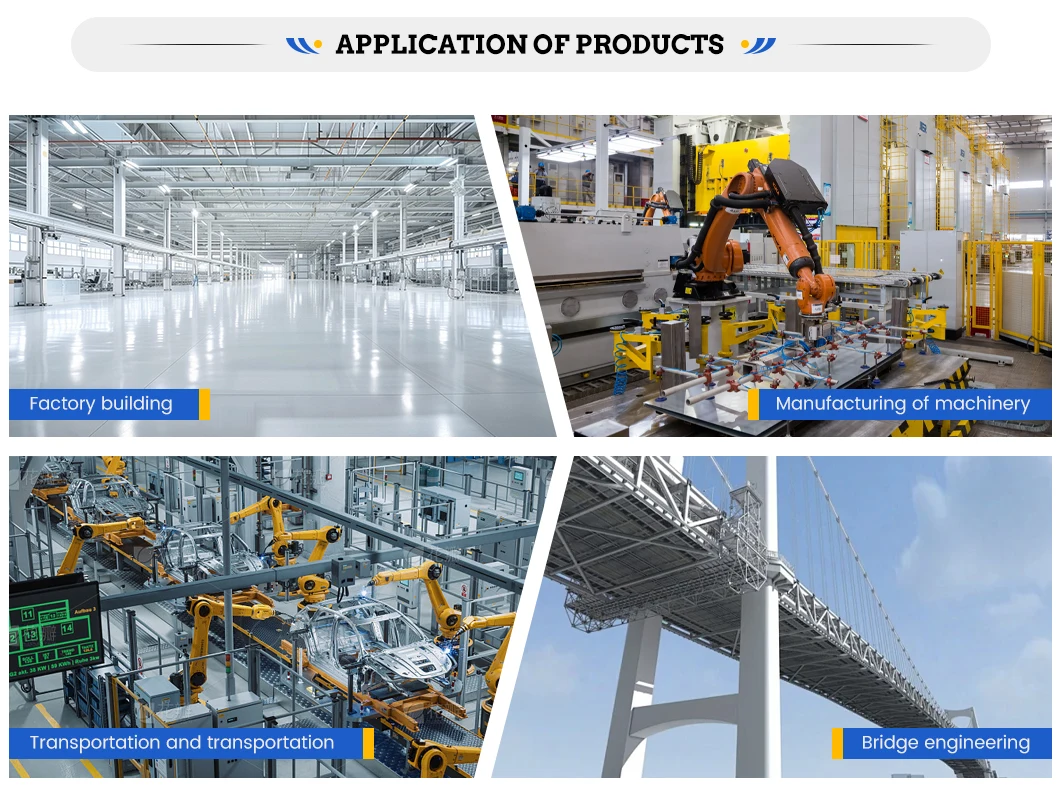

The application of channel steel includes the following four points:

Building structure: Channel steel is widely used in beams, columns, frames and other load-bearing members in buildings to provide structural stability and support.Mechanical equipment manufacturing: Channel steel is used to manufacture the frame and load-bearing structure of mechanical equipment to improve the stability and safety of equipment.Transportation:

Channel steel is used to manufacture structural support parts of vehicles, ships and rail transit to ensure structural safety and operation quality. Industrial and engineering structure:

Channel steel is widely used in Bridges, chemical equipment, fixed trays and cabinets and other industrial structures, providing necessary support and fixing. These applications demonstrate the importance and versatility of channel steel in multiple fields.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

Q: Will you delivery the goods on time?

A: Yes,we promise to provide best quality products and delivery on time no matter if the price change lot or not. Honesty is our company's tenet.

Q: How can I get your quotation as soon as possible?

A: The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours. Please send us your requirement and order information,specification(Steel grade,size,quantity,destination port),we will work out a best price soon.

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Q: Do you provide samples ? is it free or extra?

A: The sample could can provide for customer with free,but the freight will be covered by customer account. The sample freight will be returned to customer account after we cooperate.