Kangtao Steel’s ASTM A312 A270 sanitary welded tubes are engineered for industries where hygiene, corrosion resistance, and structural strength are non-negotiable. Available in 300-series stainless steel grades (304, 304L, 316, 316L), these tubes comply with global standards including ASTM A312 (for industrial piping), ASTM A270 (for sanitary applications), JIS G3459, and EN 10217. They cater to diverse needs: 304 is ideal for general use, 304L for low-carbon environments, 316 for moderate corrosion, and 316L for harsh conditions (e.g., saltwater, chemicals). Sizes range from 10mm to 2000mm outer diameter (OD) and 0.4mm to 50mm thickness, with customizable lengths.

201 304 304L 316 316L

Kangtao

ISO9001,

Grade 200, Grade 300, Grade 400

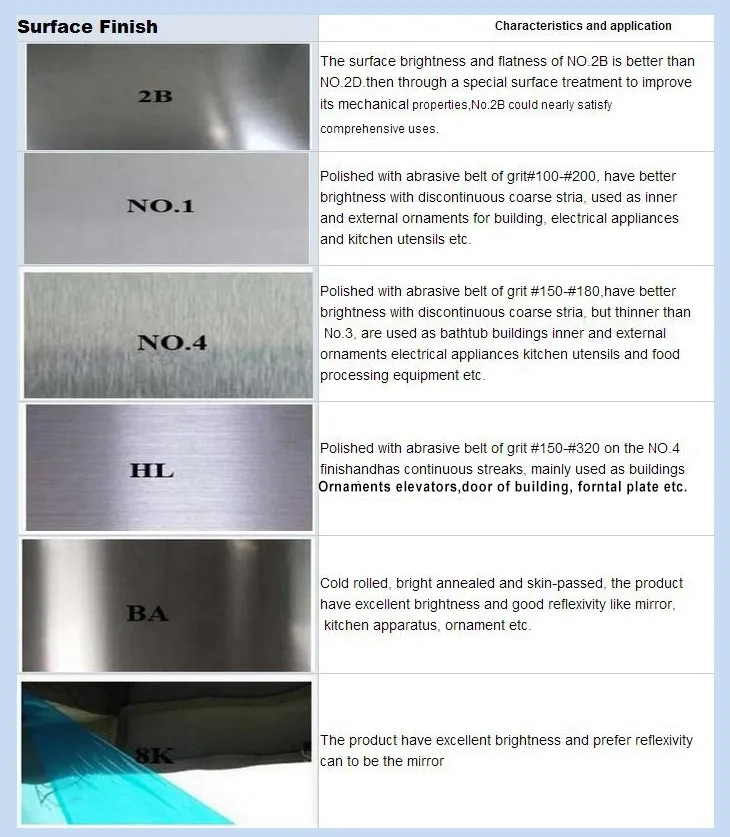

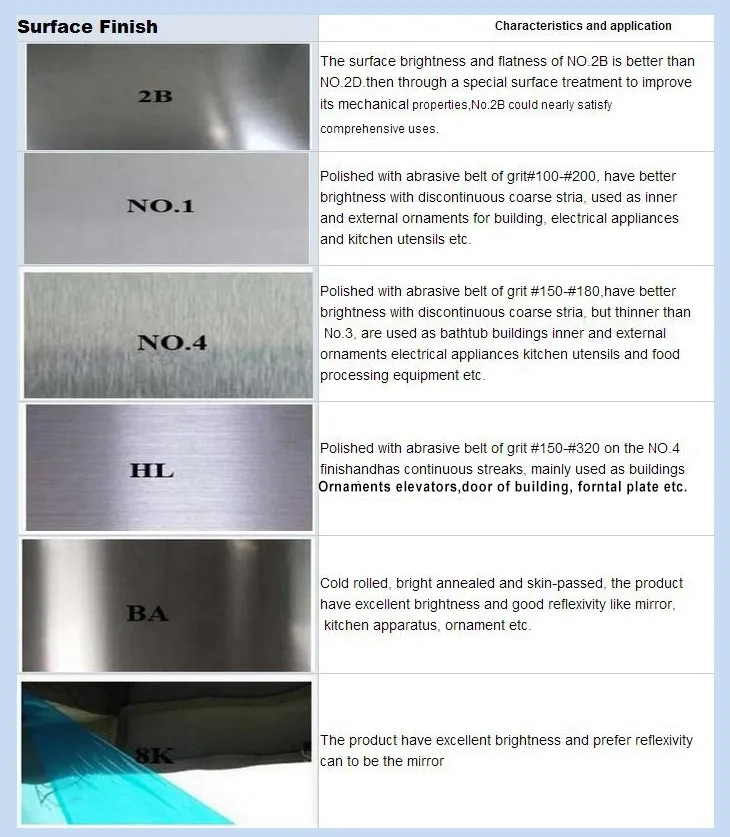

Polishing,pickling,coating

customized

0.4-50 mm

stainless steel pipe

ASTM, JIS, GB, EN

304/201/202/430/410/630/316/316L/304

customized

| Availability: | |

|---|---|

| Quantity: | |

| Product Name | Stainless Steel Pipe/Tube |

| Technology | Hot Rolled Industrial Stainless Steel Tube/Cold Rolled Decorative Stainless Steel Pipe |

| Standard | ASTM,AISI,JIS,SUS,GB,DIN,EN,etc. ASTM A312,ASTM A358,ASTM A790,ASTM A270,ASTM A554,JIS G3459,JIS G3468,JIS G3446,JIS G3448,EN10217,EN10312 |

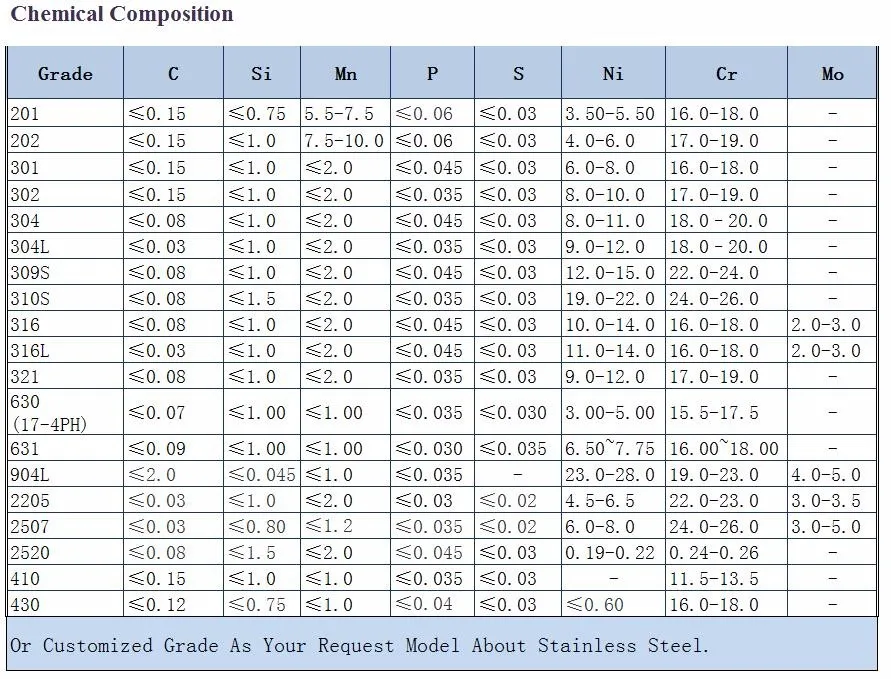

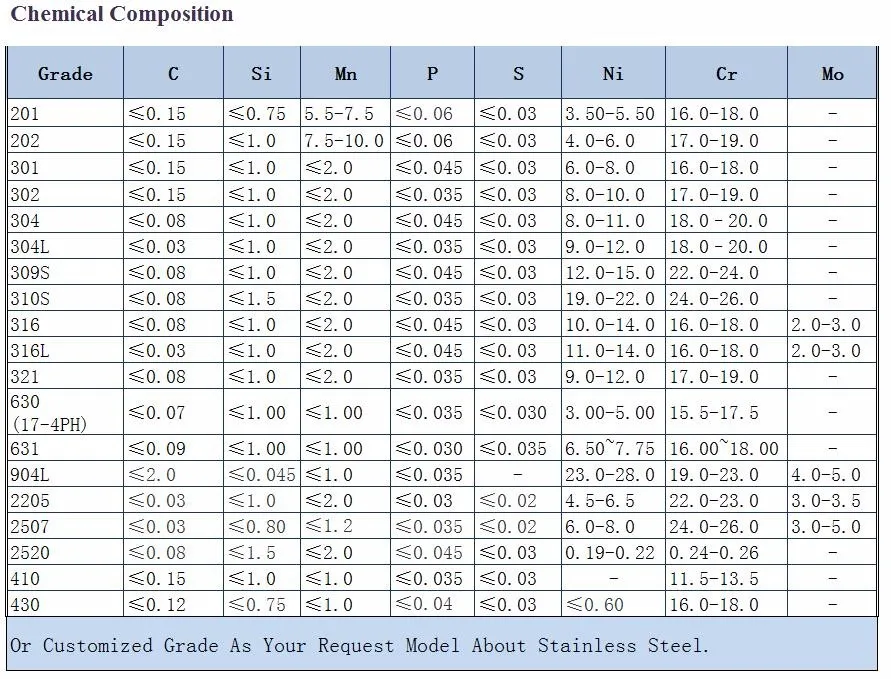

| Material | 201, 202, 301, 302, 304, 304L, 310S, 316, 316L, 321, 430 , 410, 440, 904Lect, Or Customized |

| Thickness | 0.4-50 mm |

| Outer Diameter(OD) | 10-2000mm |

| Standard | ASTM, JIS, GB, AISI, DIN, BS,EN |

| Application | Railings, Balustrade, Furniture, Fence, Decorations, Constructions, Food industry, etc. |

| Packing | Bundled wooden box or bag(According to customer's requirement) |

ASTM A270 certification ensures the tubes meet strict hygiene standards: their smooth, welded interior prevents fluid buildup and bacterial growth—critical for food, beverage, and pharmaceutical applications. The tubes are also pickled and polished to eliminate surface impurities, making them suitable for transferring liquids like milk, juice, or medication.

304/304L: Cost-effective for dry or mild-moisture environments (e.g., architectural railings, freshwater piping).

316/316L: Contains molybdenum for resistance to saltwater, acids, and chemicals (e.g., coastal buildings, chemical processing).

This variety lets you choose the right grade for your environment, avoiding overspending on unnecessary features.

The tubes use seamless moulding and precision welding to ensure leak-proof performance—essential for fluid transfer. Surface treatments include polishing (for a decorative sheen), pickling (for corrosion resistance), and coating (for extra protection). This versatility makes them suitable for both visible (e.g., balustrades) and hidden (e.g., underground piping) applications.

Food manufacturers face the risk of contamination from outdated piping. Our ASTM A270 sanitary tubes solve this: their smooth interior prevents residue buildup, and 316L grade resists corrosion from acidic foods or cleaning agents (e.g., bleach). Use them for juice processing lines, dairy farms, or brewery piping—they comply with FDA standards and reduce the need for frequent pipe replacements.

For builders working on commercial or residential projects, these tubes address the challenge of creating long-lasting, attractive railings. Choose polished 304 tubes for indoor staircases (they add a modern look) or 316L tubes for outdoor decks (they resist rain, salt, and UV damage). The tubes are easy to cut and bend, allowing for custom designs (e.g., curved balustrades) without compromising strength.

Chemical plants need piping that can withstand harsh substances like sulfuric acid or ammonia. Our 316L tubes with pickled surfaces resist corrosion, preventing leaks that could cause safety hazards or production downtime. They also comply with ASTM A312 standards for industrial piping, ensuring compatibility with existing systems.

A: Yes. All tubes comply with ASTM A270 and FDA standards, making them safe for food and beverage contact.

A: Yes. We offer OD sizes from 10mm to 2000mm. Share your project’s requirements, and we’ll manufacture tubes to match.

A: Absolutely. We provide material certificates (e.g., MTC) and compliance documents (ASTM, JIS, ISO9001) for every order.

A: For outdoor use, we recommend pickled or coated 316L tubes. Pickling removes surface oxides, while coating adds an extra layer of protection against rain and salt.

| Product Name | Stainless Steel Pipe/Tube |

| Technology | Hot Rolled Industrial Stainless Steel Tube/Cold Rolled Decorative Stainless Steel Pipe |

| Standard | ASTM,AISI,JIS,SUS,GB,DIN,EN,etc. ASTM A312,ASTM A358,ASTM A790,ASTM A270,ASTM A554,JIS G3459,JIS G3468,JIS G3446,JIS G3448,EN10217,EN10312 |

| Material | 201, 202, 301, 302, 304, 304L, 310S, 316, 316L, 321, 430 , 410, 440, 904Lect, Or Customized |

| Thickness | 0.4-50 mm |

| Outer Diameter(OD) | 10-2000mm |

| Standard | ASTM, JIS, GB, AISI, DIN, BS,EN |

| Application | Railings, Balustrade, Furniture, Fence, Decorations, Constructions, Food industry, etc. |

| Packing | Bundled wooden box or bag(According to customer's requirement) |

ASTM A270 certification ensures the tubes meet strict hygiene standards: their smooth, welded interior prevents fluid buildup and bacterial growth—critical for food, beverage, and pharmaceutical applications. The tubes are also pickled and polished to eliminate surface impurities, making them suitable for transferring liquids like milk, juice, or medication.

304/304L: Cost-effective for dry or mild-moisture environments (e.g., architectural railings, freshwater piping).

316/316L: Contains molybdenum for resistance to saltwater, acids, and chemicals (e.g., coastal buildings, chemical processing).

This variety lets you choose the right grade for your environment, avoiding overspending on unnecessary features.

The tubes use seamless moulding and precision welding to ensure leak-proof performance—essential for fluid transfer. Surface treatments include polishing (for a decorative sheen), pickling (for corrosion resistance), and coating (for extra protection). This versatility makes them suitable for both visible (e.g., balustrades) and hidden (e.g., underground piping) applications.

Food manufacturers face the risk of contamination from outdated piping. Our ASTM A270 sanitary tubes solve this: their smooth interior prevents residue buildup, and 316L grade resists corrosion from acidic foods or cleaning agents (e.g., bleach). Use them for juice processing lines, dairy farms, or brewery piping—they comply with FDA standards and reduce the need for frequent pipe replacements.

For builders working on commercial or residential projects, these tubes address the challenge of creating long-lasting, attractive railings. Choose polished 304 tubes for indoor staircases (they add a modern look) or 316L tubes for outdoor decks (they resist rain, salt, and UV damage). The tubes are easy to cut and bend, allowing for custom designs (e.g., curved balustrades) without compromising strength.

Chemical plants need piping that can withstand harsh substances like sulfuric acid or ammonia. Our 316L tubes with pickled surfaces resist corrosion, preventing leaks that could cause safety hazards or production downtime. They also comply with ASTM A312 standards for industrial piping, ensuring compatibility with existing systems.

A: Yes. All tubes comply with ASTM A270 and FDA standards, making them safe for food and beverage contact.

A: Yes. We offer OD sizes from 10mm to 2000mm. Share your project’s requirements, and we’ll manufacture tubes to match.

A: Absolutely. We provide material certificates (e.g., MTC) and compliance documents (ASTM, JIS, ISO9001) for every order.

A: For outdoor use, we recommend pickled or coated 316L tubes. Pickling removes surface oxides, while coating adds an extra layer of protection against rain and salt.